Email Us

Raydafon Gears

Your Partner for High-Performance Automotive & Industrial GearsBAB Series High Torque High Precision Planetary Gearbox (Planetary Gear Reducer)

BAB Series High Torque High Precision Planetary Gearbox (Planetary Gear Reducer)

The BAB series high precision planetary gearbox is a type of gearbox that utilizes planetary gears to provide high torque and precision in a compact design. It is commonly used in applications where high precision and high torque are required, such as robotics, automation, and machine tools.

The BAB series high precision planetary gearbox is known for its high efficiency, low backlash, and high torsional rigidity, which allows for accurate positioning and smooth operation. It is available in various ratios and sizes and can be customized to suit specific application requirements. Overall, the BAB series high precision planetary gearbox is a reliable and versatile gearbox that can be used in a wide range of applications requiring high precision and high torque.

|

|

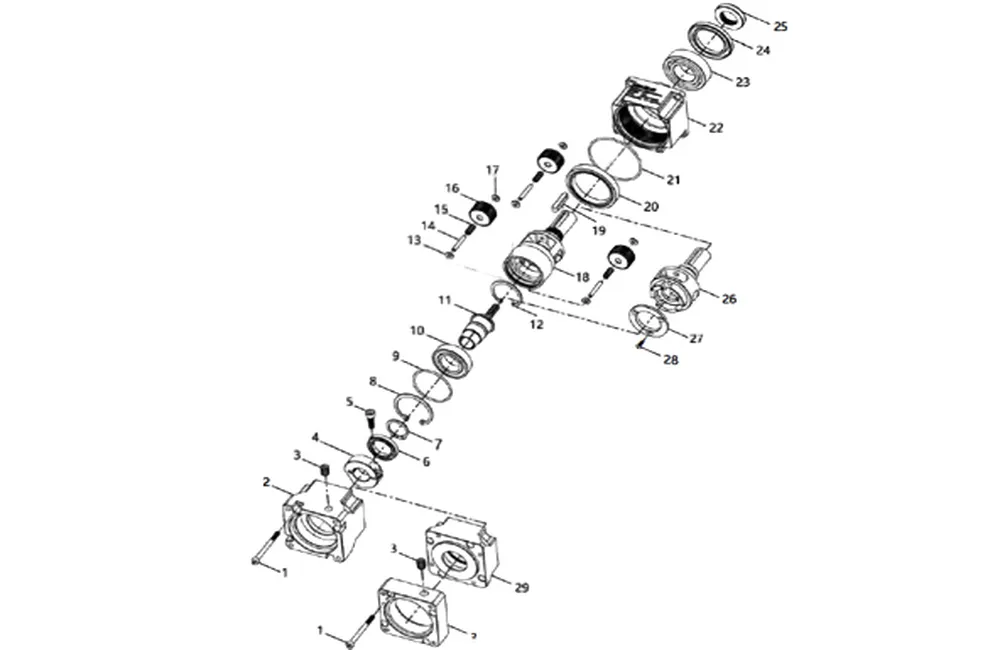

鈻岯AB Series High Precision Planetary Gearbox Parts:

| 1 | 鍐呭叚瑙掕灪閽? Inner hex screw | 11 | 澶槼杞? Sun wheel | 21 | O鍨嬫鑳跺瘑灏佸湀/0-ring |

| 2 | 鍚庣洊/ Back cover | 12 | 瀛旂敤鎸″湀/ Hole-circlip | 22 | 鍐呴娇鍦? Internal gear |

| 3 | 鍫靛ご/ Plug | 13 | 鍨湀/Washer | 23 | 杞存壙/ Bearing |

| 4 | 閿佺揣鐜?Locking ring | 14 | 婊氭煴/ Roller | 24 | 娌瑰皝/Oil seal |

| 5 | 鍐呭叚瑙掕灪閽? Inner hex scewv | 15 | 婊氶拡/ Kingpin | 25 | 閿佺揣铻烘瘝/Locknut |

| 6 | 娌瑰皝/Oil seal | 16 | 琛屾槦杞? Planet gear | 26 | 琛屾槦鏋? Planet carier |

| 7 | 杞寸敤鎸″湀/ Shaft-circlip | 17 | 鍨湀/Washer | 27 | 鍨湀/Washer |

| 8 | 瀛旂敤鎸″湀/ Hole-circlip | 18 | 琛屾槦鏋? Planet crrier | 28 | 娌夊ご铻洪拤/Countersunk head screw |

| 9 | O鍨嬫鑳跺瘑灏佸嚳/ 0-ring | 19 | 閿? Key | 29 | 鍚庣洊/ Back cover |

| 10 | 杞存壙/ Bearing | 20 | 杞存壙/ Bearing | 30 | 杩炴帴鏉? Connecting plate |

鈻岯AB Series High Precision Planetary Gearbox聽Design:

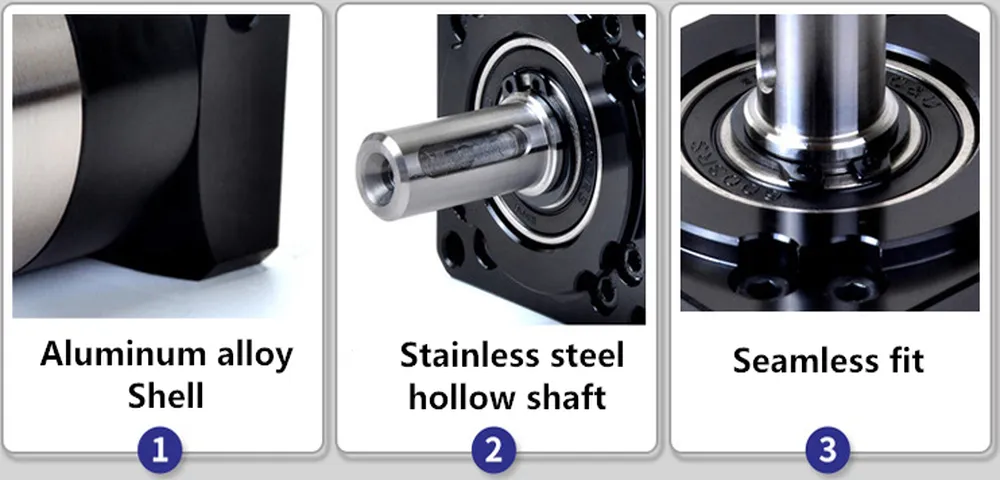

- The housing and flange of the planetary gearbox are made of Aluminum alloy die-casting ADC12.

- Planetary gear systems are made of high-precision gears.

- The material of Ring Gearsis 40Cr.

- The planetary gear material of the BAB precision planetary gearbox is 20CrMnTi, the surface hardness value of the BAB planetary reducer is about HRC58~62, and the inner hardness data is around HRC33~40.

- The input end of the planetary gearbox is equipped with a motor adaptor and keyed hollow shaft.

- Output configurations of the BAB precision planetary reducer gearbox are keyed solid shaft-output method, Keyless solid shaft output, or output for holes. It depends on the specific needs of customers.

- Applicable motors are servo motors and stepper motors for all Japanese, German, Taiwan,ese, or American brands.

鈻岯AB Series High Precision Planetary Gearbox Advantages:

The precision planetary gearbox is a new-generation product independently developed by our company. It integrates advanced technology at home and abroad and has main advantages.

1. Noise less than 65 dB.

2. The backlash can be within three arc minutes for a single stage and five arc minutes for a double stage.

3. The single-stage efficiency is over 95%, and the double-stage efficiency is around 92%.

4. High input speed: up to 8000rpm.

5. High torque: higher than the torque of the available standard planetary reducer.

6. High stability: using high-strength alloy steel, the whole gear is hardened, not only surface hardening but also guarantees service life and long-term use and maintains the initial speed.

7. The high reduction ratio adopts a modular design, the planetary gearboxes can be connected, and the speed ratio can reach more than one thousandth.

鈻岯AB Series High Precision Planetary Gearbox Specification:

| Series | Stage | Models | Ratio | Rated Torque | Output Flange Dia. | Output Shaft Dia. | Backlash | Efficiency |

| BAB Planetary Gearbox | 1 Stage | BAB042, BAB060, BAB090, BAB115, BAB142, BAB180, BAB220 | 3, 4, 5, 6, 7, 8, 9, 10 | 14N.m~2000N.m | 42mm~220mm | 桅13, 桅16, 桅22, 桅32, 桅40, 桅55, 桅75 | 鈮?, 鈮?, 鈮? arcmin | 鈮?7% |

| 2 Stage | BAB042, BAB060, BAB060A, BAB090, PAB090A, BAB115, BAB142, BAB180, BAB220 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | 14N.m~2000N.m | 42mm~220mm | 桅13, 桅16, 桅22, 桅32, 桅40, 桅55, 桅75 | 鈮?, 鈮?, 鈮? arcmin | 鈮?4% |

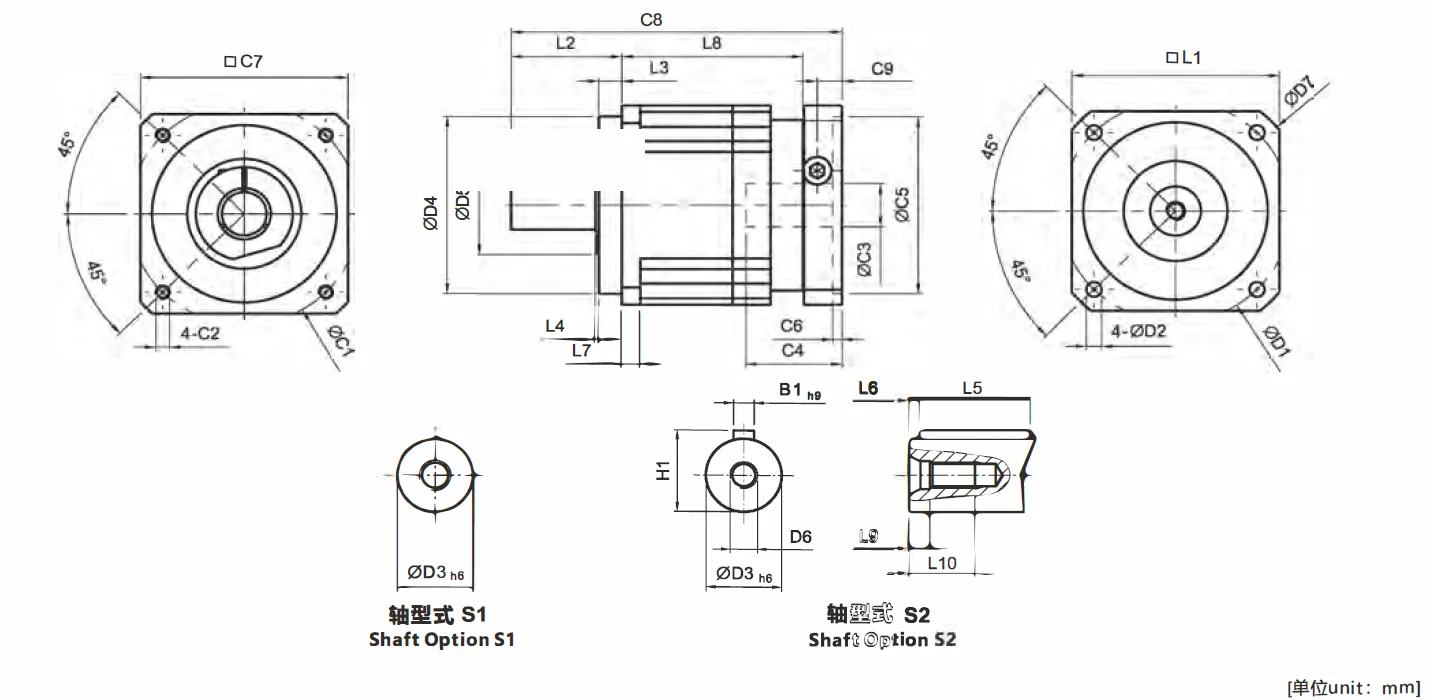

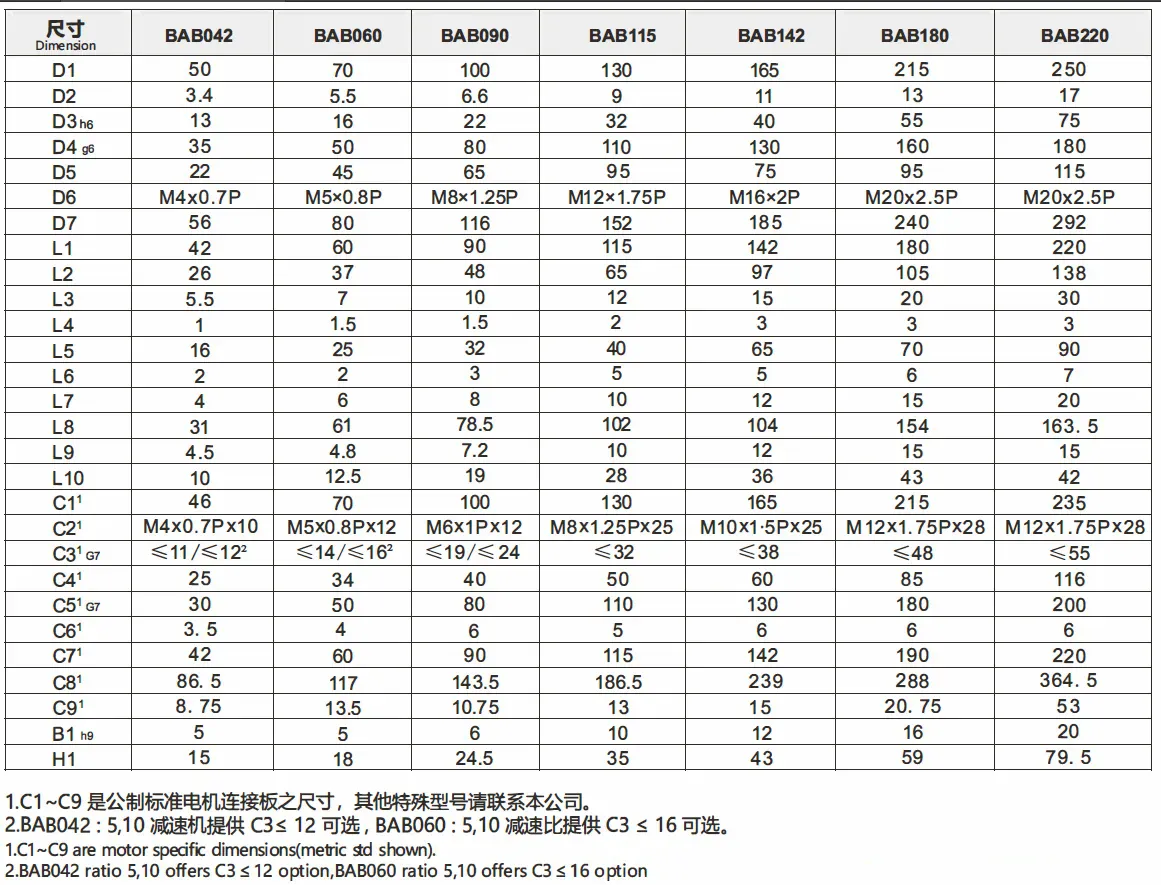

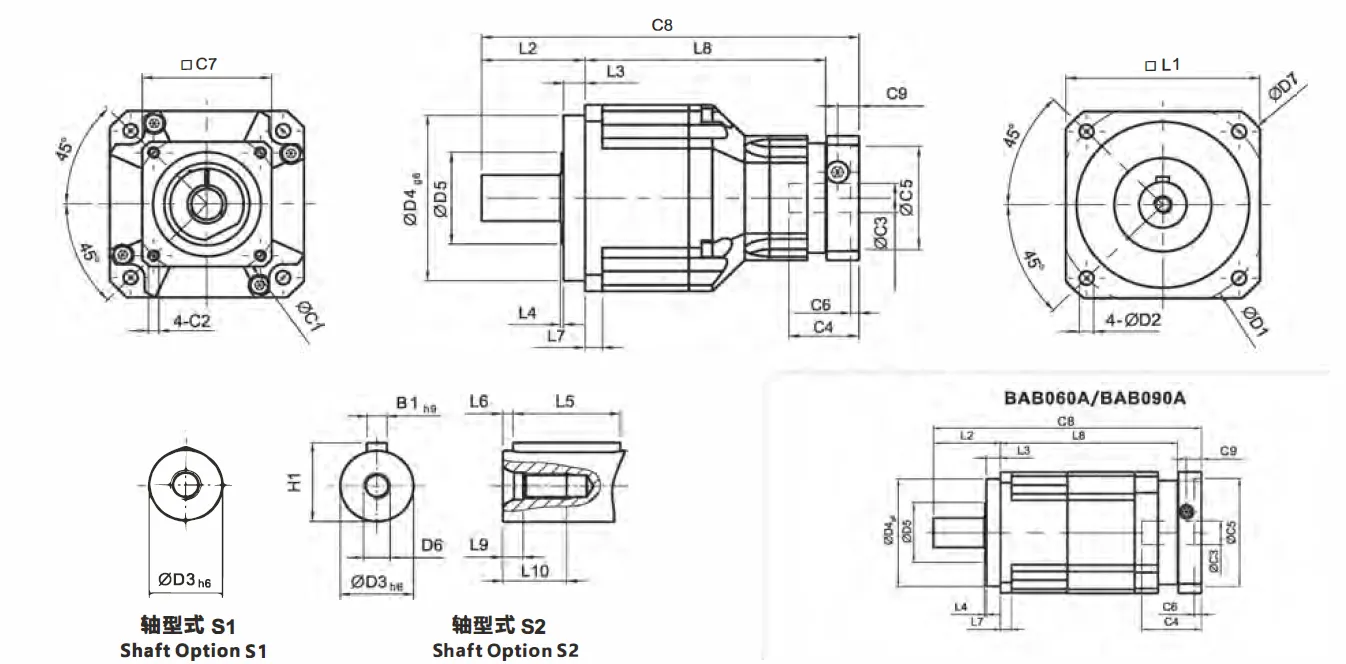

鈻岯AB Series High Precision Planetary Gearbox Outline Dimension:

鈻?/strong> 1 Stage Planetary Gearbox (Ratio i=3~10)聽

鈻?/strong> 2 Stage Planetary Gearbox (Ratio i=15~100)聽

鈻?/strong>BAB Series High Precision Planetary Gearbox Applications Scenario:

Precision planetary gear reducers are widely used in the following fields

1. Aerospace and military industries.

2. Healthcare, Electronics Information Technology Industry

3. Industrial robots, production automation, and CNC machine tool manufacturing industries.

4. Industries include automobile manufacturing, textile, printing, food, metallurgy, environmental protection engineering, warehousing, and logistics.

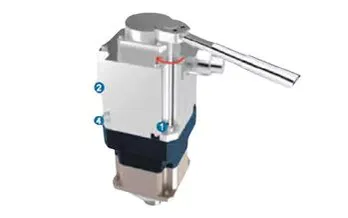

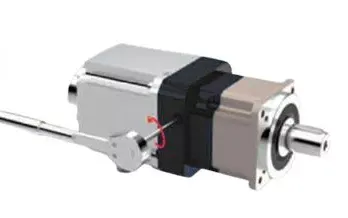

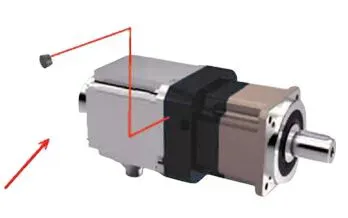

鈻?/strong>How to Install a Planetary Gearbox on a Servo Motor?

Step One:聽聽wipe off the anti-rusting additive and grease on the motor shaft.

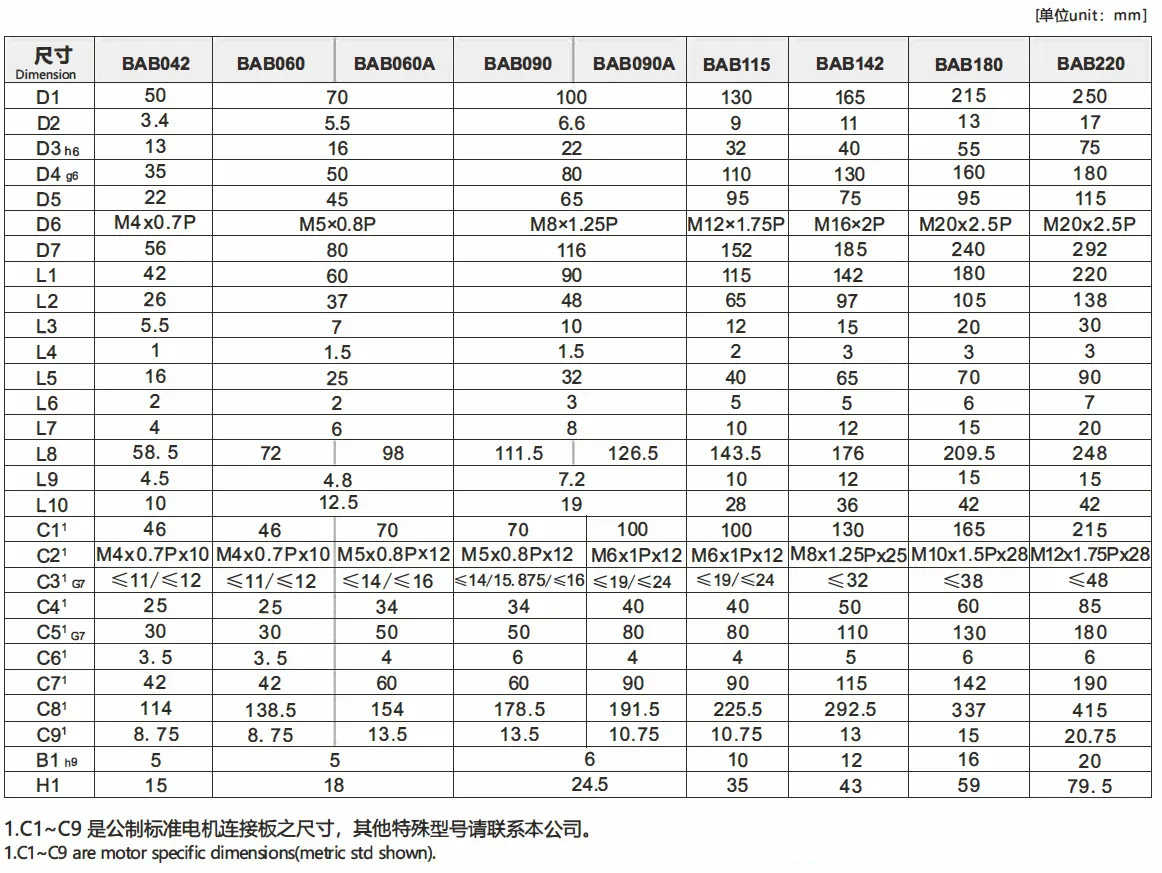

Step Two:聽Remove the rubber plug.

Step Three:聽Rotate the input shaft to align the fastening bolt with the plug hole. Please make sure that the cap screw is loosened. If a shaft sleeve is attached, please install it according to the figure below.

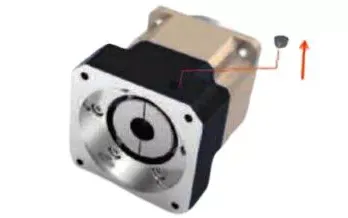

Step Four:聽Place the reducer vertically in a flat place so that the motor mounting face of the planetary gearbox is upward. Insert the motor shaft into the input shaft slowly to avoid hitting the input shaft. Please make sure that the flange of the motor is close to the flange of the servo gearbox. Tighten the motor mounting bolts based on the designated tightening torque.

Step Five:聽Use a torque wrench to tighten the clamping bolt according to the designated fastening torque.

Step Six:聽Install the rubber bolt. The whole installation procedure is finished.

| Step One | Step Two | Step Three |

|

|

|

| Step Four | Step Five | Step Six |

|

|

|

鈻岺igh Precision Planetary Gearbox Lubrication:

Lubrication is an important aspect of maintaining the performance and longevity of a high precision planetary gearbox. Proper lubrication can help reduce friction and wear, dissipate heat, and prevent corrosion.

The type of lubricant used will depend on the specific application and operating conditions of the high precision planetary gearbox. Generally, a high-performance synthetic lubricant with a high viscosity index and good thermal stability is preferred. The lubricant should also be compatible with the materials used in the gearbox, such as the gears, bearings, and seals.

It is important to follow the manufacturer's recommendations for lubrication intervals and quantities to ensure optimal performance and lifespan of the gearbox. In addition, regular inspections of the high precision planetary gearbox and lubrication system should be performed to detect any signs of contamination or degradation of the lubricant, which can lead to premature failure of the planetary gearbox.

To lubricate a planetary gearbox, the lubricant is typically introduced through a fill port and circulated throughout the gearbox using a pump or other means. Some high precision planetary gearboxes may have specialized lubrication systems, such as oil mist or oil jet systems, to provide precise and efficient lubrication to critical components.

鈻?/strong>We Also Provide Other Series Planetary Gearbox:

鈻岺igh Precision Planetary Gearbox Manufacturers

HZPT Mechanical & Electrical Co., Ltd. is a professional manufacturer of聽planetary gearbox and electric motors. The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, and the total number of staff is more than 200. We have passed the ISO9001:2015 international quality management system standard certificate, CCC national compulsory product certificate, and CE certificate. We have developed advanced management software such as ERP to keep pace with international standards. In order to serve customers better, the company actively cooperates with colleges and universities to develop new products and improve existing products.

鈻?/strong>FAQ

Q1: What is a high torque planetary gearbox?

A: A high torque planetary gearbox is a type of gearbox that uses planetary gears to provide high torque output. It is designed to handle high loads and provide precise, efficient power transmission in a compact and robust package.

Q2: What are the benefits of a high torque planetary gearbox?

A: The benefits of a high torque planetary gearbox include high torque capacity, high efficiency, low backlash, and high precision. It is also compact in size, making it ideal for use in applications where space is limited.

Q3: What applications are high torque planetary gearboxes used in?

A: High torque planetary gearboxes are used in a wide range of applications, including robotics, automation, machine tools, printing machinery, packaging machinery, and many others. They are particularly useful in applications that require high precision and high torque output.

Q4: How do high torque planetary gearboxes work?

A: High torque planetary gearboxes work by using a planetary gear system, which consists of a sun gear, planet gears, and a ring gear. The sun gear is typically driven by a motor, and the planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it drives the planet gears, which in turn rotate the output shaft, producing high torque output.

Q5: What factors should be considered when selecting a high torque planetary gearbox?

A: Thefactors that should be considered when selecting a high torque planetary gearbox include the required torque capacity, input speed, output speed, efficiency, backlash, size, and mounting options. It is also important to consider the specific application requirements, such as the operating environment, load type, and duty cycle. Consulting with a gearbox expert or supplier can help ensure that the gearbox selected is the best fit for the specific application.

-

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

-

Tel

-

E-mail

Contact Us

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © 2025 Raydafon Technology Group Co.,Limited All Rights Reserved.