Email Us

Raydafon Gears

Your Partner for High-Performance Automotive & Industrial GearsCycloidal Gearbox BLD Vertical Cycloid Reducer (Cycloidal Gear Reducer) for Mixing Equipment

Cycloidal Gearbox BLD Vertical Cycloid Reducer (Cycloidal Gear Reducer) for Mixing Equipment

The BLD vertical cycloidal gearbox is a type of planetary cycloidal gearbox that is used in a variety of industries, including petroleum, environmental protection, chemical, cement, transport, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, and power generation. It is characterized by its high-speed ratio, high efficiency, compact size, and smooth running noise.

The BLD vertical cycloidal gearbox uses a planetary transmission principle, which means that the input shaft and output shaft are on the same axis line. This allows for a smaller machine model and a more compact design. The BLD vertical cycloidal gearbox also features a cycloidal needle tooth design, which provides smooth running noise and low cycloidal noise. The number of meshing teeth is more than in other types of gearboxes, which results in a larger overlap coefficient and a reduction in vibration and noise.

The BLD vertical cycloidal gearbox is a versatile and reliable gearbox that can be used in a variety of applications. It is especially well-suited for applications that require high-speed ratios, high efficiency, and compact size.

鈻?/strong>BLD Vertical Cycloidal Gearbox Specifications

| Product Name: | BLD Cycloidal Drive Gearbox | Gearing Arrangement: | Cycloidal |

| Customized support: | OEM, ODM | Housing Material: | Cast Iron |

| Place of Origin: | Zhejiang, China | Gear Material: | GCR15 steel |

| Brand Name: | EPT | Color: | Blue, Green, or Customized |

| Input Power: | 0.25kW-55kW | Mount Position: | Horizontal(foot) mounted or Vertical(flange) Mounted |

| Output Torque: | 48.3N/m锝?9400N/m | Packing: | plywood case |

| Input Speed: | 750-3000rpm | Warranty Period: | One year |

| Output Speed: | 11-280rpm | Input Configurations: | Equipped with Electric Motors, IEC-normalized Motor Flange, Keyed Solid Shaft Input |

| Ratio: | 9-1849 | Output Configurations: | Keyed Solid Shaft Output |

鈻?/strong>BLD Vertical Cycloidal Gearbox Design

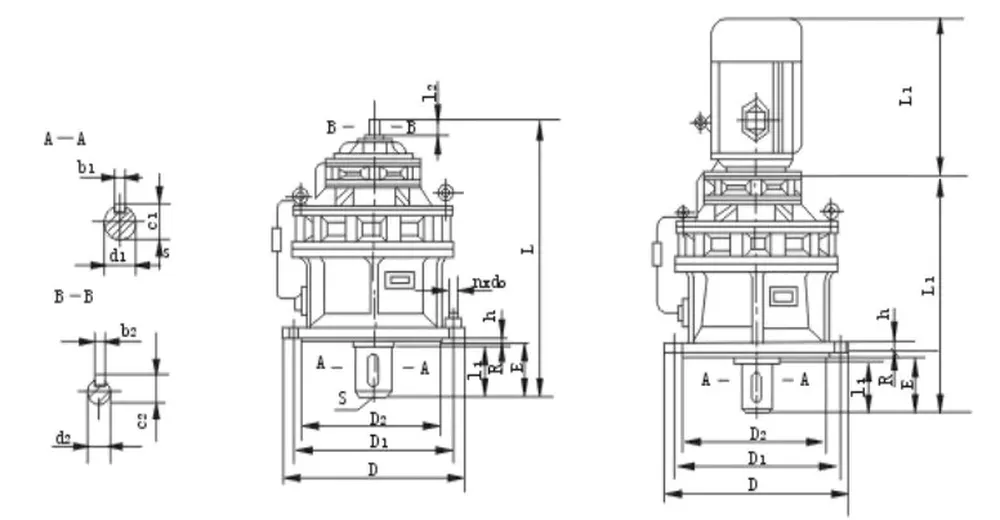

鈻?/strong>BLD Vertical Cycloidal Gearbox Mounting Dimension

鈻?/strong>BLD Vertical Cycloidal Gear Reducer Features

The BLD vertical cycloidal gear reducer (also known as the cycloidal gearbox or cycloidal speed reducer) is a type of gearbox that has several features that make it a popular choice for many industrial applications. Here are some of its key features:

1. High speed ratio:聽Single-stage transmission can achieve a deceleration ratio of 1:87, and the efficiency is more than 90%. If the multi-stage transmission is used, the deceleration ratio will be larger.

2. High efficiency: The efficiency of the BLD vertical cycloidal gear reducer is more than 90%, which means that it can transmit more power with less energy loss.

3. Compact size:聽The planetary transmission principle allows for a smaller machine model and a more compact design.

4. Smooth running noise:聽The cycloidal needle tooth design provides smooth running noise and low cycloidal noise.

5. Low vibration:聽The number of meshing teeth is more than in other types of gearboxes, which results in a larger overlap coefficient and a reduction in vibration.

6. Reliable use and long service life:聽Because the main parts are made of high carbon chromium steel, high strength is obtained by quenching (HRC58-62), and rolling friction is used in some transmission contacts, so the service life is long.

7. Wide application range: The BLD vertical cycloidal gear reducer can be used in a variety of industries, including聽petroleum, environmental protection, chemical, cement, transport, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction,聽and power generation.

Overall, the BLD vertical cycloidal gear reducer is a versatile and reliable gearbox that can be used in a variety of applications. It is especially well-suited for applications that require high-speed ratios, high efficiency, and compact size.

|

|

鈻岺ow Does a Cycloidal Gearbox Work?

A cycloidal gearbox, also known as a cycloidal speed reducer, is a type of gearbox that uses a cycloidal mechanism to transmit power between a motor and an output shaft. The cycloidal gearbox consists of three main components: a stationary ring gear, a rotating eccentric bearing, and a set of rollers that revolve around the eccentric bearing.

When the input shaft (connected to the motor) rotates, it drives the eccentric bearing to rotate around the stationary ring gear. As the eccentric bearing rotates, the rollers move around the eccentric bearing, generating both rotational and planetary motion. This results in an output shaft that rotates at a slower speed than the input shaft, but with significantly increased torque.

The rollers in a cycloidal gearbox are arranged in a cycloidal pattern, which means they move in a path that is not circular but comprised of a series of arcs. The eccentric bearing rotates in the opposite direction to the input shaft, which causes the rollers to move in the opposite direction to the rotation of the eccentric bearing. This movement generates a series of overlapping tooth profiles, which provide a smooth and constant transfer of power between the input and output shafts.

Cycloidal gearboxes are known for their high precision and high torque transmission capabilities, as well as their compact and lightweight design. They are commonly used in industrial machinery, robotics, and other applications where high precision and torque are required.

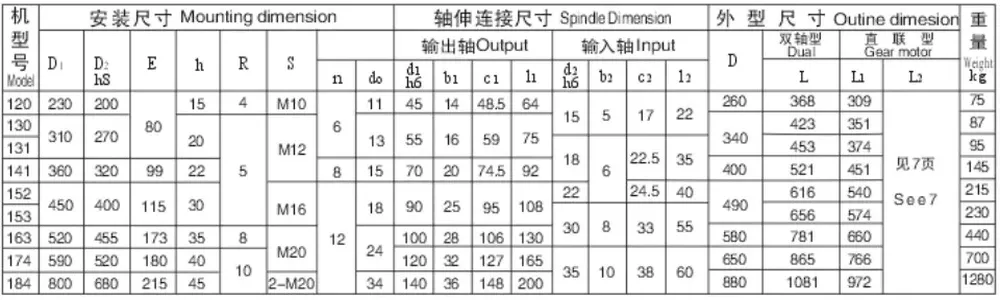

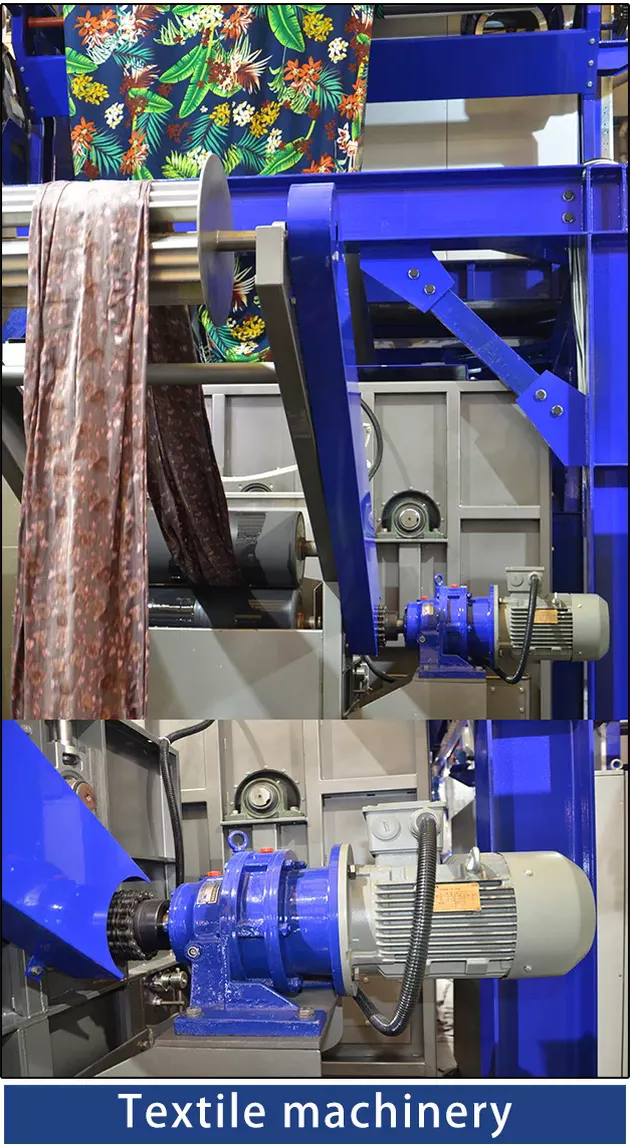

鈻?/strong>BLD Vertical Cycloidal Gearbox Applications

Cyclo drive gearbox adopts meshing cycloid pin gear, planetary transmission principle, so usually also called planetary cycloid reducer, the planetary cycloidal gearbox can be widely used in petroleum, environmental protection, chemical, cement, transport, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation, and other industries, as a driver or reduction gear, the machine is divided into horizontal, vertical, biaxial and straight league such as assembly way. Its unique stable structure, in many cases, can replace the ordinary worm gear reducer and cylindrical gear reducer; therefore, a planetary cycloidal pinwheel reducer is widely used in various industries and fields by the majority of users generally welcome.

|

|

|

鈻?/strong>Cycloidal Reducer Gearbox Use Condition

1. The cycloidal gearbox is allowed to be used in the continuous working system while allowing the positive and negative directions to operate in two directions. Some types of the cycloidal gearboxes are only allowed to rotate in one direction.

2. The input shaft speed, rated speed of 1500 rpm/min, in the input power of greater than 18.5 kilowatts, is recommended to use 960 RPM / 6 pole motor matching.

3. Horizontal installation cycloidal gearbox working position is horizontal position. At installation, the maximum horizontal inclination is generally less than 15 degrees. More than 15 degrees, other measures should be adopted to ensure adequate lubrication and prevent oil leakage.

4. The output shaft of the cycloidal gearbox can not be subjected to larger axial and radial forces, and other measures must be taken in the case of larger axial and radial forces.

鈻?/strong>Cycloidal Gearbox Lubrication Requirements

2. Cycloid gearbox generally chooses 40# or 50# mechanical oil lubrication at room temperature. To improve the performance of the reducer and extend the service life of the cycloidal drive gearbox, it is recommended to use 70# or 90# extreme pressure gears. Lubricating oil should be reconsidered when working under high and low-temperature conditions.

3. The vertical installation of the planetary cycloid reducer gearbox must prevent the oil pump from cutting off the oil to avoid damage to the parts of the reducer.

4. When refueling, you can turn the breather cap on the upper part of the seat to refuel. When draining the oil, turn the drain plug at the bottom of the main seat to drain the dirty oil. There is no lubricating oil inside the reducer when it leaves the factory.

5. New oil should be replaced for 100 hours after the first refueling operation (clean the dirty internal oil), and then continue to work afterward. Replace every six months (8-hour work system). If the working conditions are wrong, the oil change time can be appropriately shortened. The practice has proved that frequent cleaning and oil change of the cyclo drive reducer(such as 3-6 months) play an essential role in extending the service life of the cyclo drive reducer. Lubricating oil should be frequently added during use.

6. The factory-made cycloidal gearbox has been greased and replaced every six months.

鈻岰hina Cycloidal Gearbox Manufacturers

Chinese gearbox speed reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gearboxes, planetary gearboxes, and worm gearboxes, as well as various special transmission devices such as speed-increasing devices and speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery, and petrochemical industries.

HZPT is a professional manufacturer of cycloidal gearboxes in China. The main products are the X series cycloidal gearbox, B series cycloidal gearbox, 8000 series cycloidal gearbox, BWD cycloid gearbox reducer, XW BW cycloid gearbox, ZQ series cylindrical gearbox, K, F, S, R series helical gearboxes, EP-NMRV series worm gearboxes, WP series worm gearboxes, SWL series worm gear screw jack, ATA series shaft mounted gearbox, SMR series shaft mounted gearbox, The above products have passed the ISO9002 international quality system certification, and are widely used in metallurgy, mining, cement, building materials, chemical industry, plastics, paper making, hoisting, and other industries, and can manufacture various non-standard gearbox and accessories according to the needs of applications.

-

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

-

Tel

-

E-mail

Contact Us

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © 2025 Raydafon Technology Group Co.,Limited All Rights Reserved.